A2 and A4 Stainless Steel are widely used grades of stainless steel, especially in applications requiring high corrosion resistance. These two grades comply with the international ISO 3506 standard and are commonly used in bolts, nuts, screws, and metal components exposed to various environments.

1. A2 Stainless Steel (Equivalent to Grade 304)

Key Properties:

-

Made from AISI 304 stainless steel

-

Composed of 18% Chromium (Cr) and 8% Nickel (Ni)

-

Good corrosion resistance in general environments

-

Not highly resistant to salt spray or harsh chemicals

-

Non-magnetic or very low magnetic permeability

Applications:

-

Used in the food and kitchenware industries

-

Construction and architectural fittings

-

Machinery and general-purpose equipment not exposed to aggressive chemicals

-

Not suitable for marine use or highly humid environments

2. A4 Stainless Steel (Equivalent to Grade 316)

Key Properties:

-

Made from AISI 316 stainless steel

-

Composed of 16–18% Chromium (Cr), 10–14% Nickel (Ni), and 2–3% Molybdenum (Mo)

-

Molybdenum improves resistance to chemical corrosion and seawater

-

Better resistance to salt spray and harsh conditions than A2

-

Non-magnetic or very low magnetic permeability

Applications:

-

Excellent long-term rust prevention

-

Ideal for marine and chemical industries

-

Used in food and pharmaceutical manufacturing requiring hygiene and contamination-free equipment

-

Suitable for environments with exposure to seawater or aggressive chemicals

-

Recommended for equipment requiring high durability and long service life

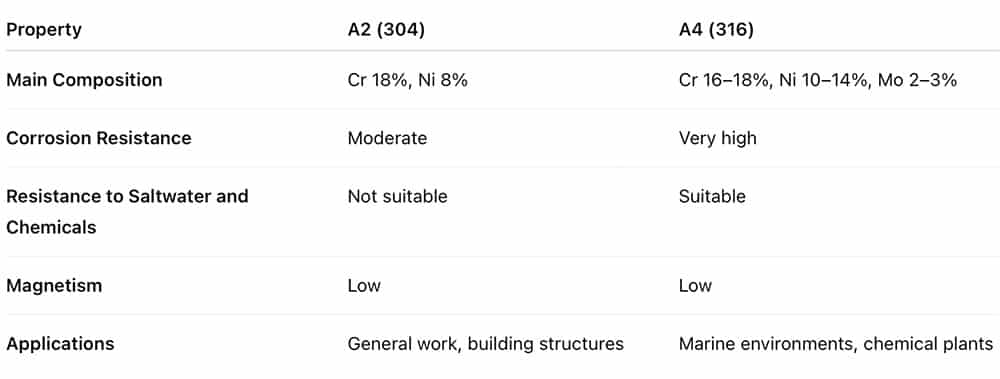

Summary of the differences between A2 and A4

How to Choose:

-

For general-purpose use, choose A2 (304) — it is more affordable and sufficient for standard applications.

-

For use in environments with salt spray, seawater, or chemicals, choose A4 (316) — it offers greater durability and corrosion resistance.

Summary:

A2 (304) is suitable for general use, while A4 (316) is ideal for high-durability needs in harsh environments. For long-term Lifeline system installations (lasting decades), A4 is recommended due to its rust resistance. If cables rust or corrode significantly, they must be replaced immediately for safety, which increases maintenance costs. However, if budget is limited, A2 is still an acceptable option.